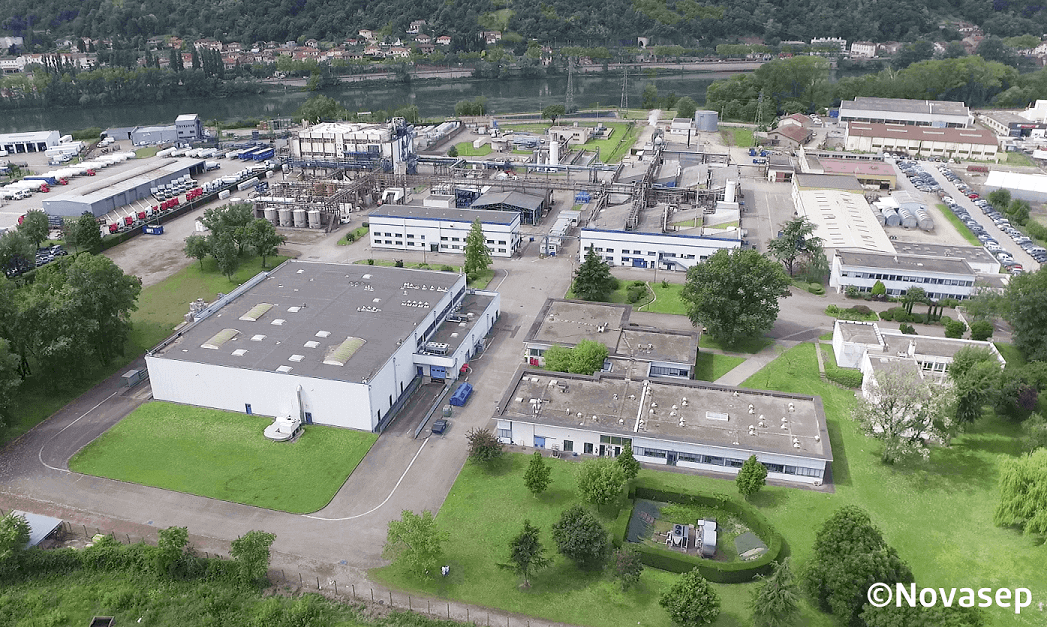

Photo Credit: Novasep

Novasep, a leading supplier of services and technologies for the life sciences industry, is investing €6.5 million to expand capacity & increase flexibility in an API manufacturing workshop at its Chasse-sur-Rhône site (69 - France).

The revamping of this workshop and installation of two new synthesis reactors (4000L Hastelloy & 1600L glass lined) is intended to increase the plant flexibility and its capacity for low to medium volume APIs, addressing the growing needs of the industry for targeted therapies. The two new reactors are equipped with a high-performance thermal system & benefit from a high level of automation. The project also involves repositioning the high-pressure hydrogenation reactor, (1500L,15bar), currently located in the workshop, in a new dedicated area.

Work has already started, and the construction of the utilities building is nearing completion. This investment will be fully operational by the end of 2021.

"Upgrading this workshop with the addition of two new reactors will enable us to continue modernizing our Chasse-sur-Rhône site's API manufacturing facilities, whilst improving flexibility and productivity ", says Jean Bléhaut, president of the Synthesis Solutions Business Unit of Novasep. "These investments will also reduce our environmental impact by optimizing energy consumption. This is an opportunity for us to respond to social and environmental challenges using technological advances.”

It also enhances the safety of employees and minimization environmental impact. All of this contributes to our Rise-2 growth strategy." adds Dr. Michel Spagnol, President and CEO of Novasep.

In 2018 a new 5000L cryogenic Hastelloy reactor was added. Containment capabilities have been reinforced with a new 1.5m² Hastelloy filter drier equipped with isolator for handling highly potent compounds. The pilot plant has been extended with a third clean room and a new Hastelloy filter drier. Finally, the analytical laboratories have been extended & additional equipment installed (LC-MS GC-MS).