QUALITY CONTROL IN MANUFACTURING

Quality control (QC) is a process that dictates the manufacturer’s ability to ensure that customers receive defect-free products that meet their needs. While QC done the wrong way can easily put consumers at risk, effective QC ensures the use of best practices and a strict adherence to standards to deliver high-quality products. This not only helps manufacturers with cost management, brand damage and liability protection, less waste production, reduced risk of delays in the supply chain, and on-time product delivery, but also improves their reputation among customers. The assurance and delivery of quality products promotes customer loyalty, repeat business, and new customers. It also can contribute to a positive branding of the product and the manufacturer, as well as a better position in the market.

WHAT DOES QUALITY CONTROL HAVE TO OFFER?

The delivery of safe, quality, and compliant products is critical in manufacturing, but rising economic, regulatory, and technological pressures have left companies facing an uphill battle to deliver sufficient goods to market without compromising on their quality or increasing expenditure.

The use of proper QC procedures means manufacturers can better manage the safety of their products, streamline and improve laboratory operations, and reduce the risk of recalls to get more products to consumers faster. Routine monitoring of manufacturing processes and products can help ensure little variation and avoid design issues, ultimately saving time, money, and resources. The creation of procedures to identify and handle the relevant defects and issues, and making the necessary changes required, fully characterize an effective QC program.

MANAGING QUALITY CONTROL PROCESSES – THE STARLIMS APPROACH

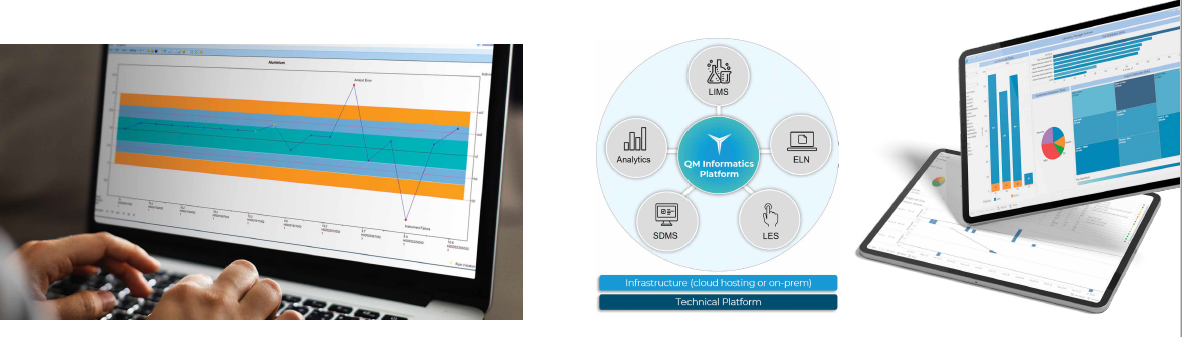

STARLIMS offers a unified quality manufacturing informatics solution that can tackle this challenge by streamlining processes and improving efficiencies in a holistic approach to QC and lab testing operations. The STARLIMS Quality Manufacturing (QM) Informatics Platform seamlessly integrates the Laboratory Information Management System (LIMS) with the Scientific Data Management System (SDMS), Laboratory Execution System (LES), Electronic Laboratory Notebook (ELN), and Advanced Analytics solution into one comprehensive technology platform. The core features of STARLIMS’ QM platform focus on ensuring data integrity, driving laboratory efficiency, simplifying testing equipment integration, streamlining lab and quality documentation management, and vigorous process monitoring.

The fast and accurate monitoring of lab data and QC processes can streamline research workflows. STARLIMS LIMS solution helps speed deployment and time-to-value with lower operating costs. The provision of automated configuration functionalities and advanced integration capabilities, as well as more than 15 pre-built, industry specific and out-of-the-box (OOTB) workflows by the STARLIMS QM platform makes it easy for labs to standardize and accelerate their lab and quality data collection processes.

The documentation of laboratory methods and standard operating procedures using lab notebooks is an integral aspect of research culture and ensures data integrity with consistent method creation and execution. STARLIMS ELN offers a digitized approach where a centralized electronic lab notebook allows for automated data capture in lab instruments, creating calculations on the run, and recording interim result data in tables. It also provides a flexible interface for capturing and storing lab data in a collaborative environment.

The paperless approach is also utilized by STARLIMS LES, providing real-time documentation, and supporting SOP compliance. This not only helps reduce transcription errors at the bench, but also drives efficiency toward test method execution from any location and at any time, further improving lab productivity and ROI.

To keep up with the large amount of data featured in modern-day labs, STARLIMS SDMS hosts a central repository for all lab data and documentation, thus eliminating data silos and enabling global collaboration amidst various laboratories. The system’s automated data capture and extraction option easily integrates with lab instruments and other systems in the lab’s LIMS, reducing the risk of manual errors and improving lab efficiency. Lastly, lab managers can simultaneously monitor lab quality control processes and make related critical decisions faster, and with better data using STARLIMS Advanced Analytics. STARLIMS Advanced Analytics further enables lab managers to create their own visualizations and reports, identify trends, patterns, bottlenecks, and make data-driven decisions to improve quality control and lab operations.

Overseeing this array of quality control operations can be daunting for any lab manager, especially with the added pressure of developing the right IT infrastructure. STARLIMS’ flexible options for on-premises, cloud hosting, and cloud subscription models via Amazon Web Services provides lab managers the ability to scale on the run and launch quickly without unplanned infrastructure costs.

CONCLUSION

Quality control is paramount to delivering safe, compliant, and quality products that meet customer expectations. This is particularly important in the manufacturing industry where there is an inherent need to balance prompt delivery of goods without compromising on quality or expenditure. With the countless systems, complex workflows, and large amounts of data that now pervade modern day laboratories and industries, the management of quality control processes is a difficult endeavor. With a comprehensive platform and flexible infrastructure, the STARLIMS’ QM Platform helps laboratories reach their quality control objectives by simplifying these complex processes, and ex-tending data collection beyond the lab without compromising on speed, security, and functionality. By focusing on accelerating innovation to New Product Introduction (NPI), expediting batch release, and increasing quality control and lab productivity, STARLIMS delivers a unified manufacturing informatics solution that not only helps organizations reach their compliance initiatives and reduce business risk, but bring quality products to market faster.

Original source from Lab Manager: https://www.labmanager.com/in-focus/simplify-your-lab-s-quality-control-initiatives-30203

-----------------------------

Contact STARLIMS Experts: SalesIndia@starlims.com